Chemical etching or metal etching or Photo etching is a form of processing that uses acids, bases or other chemicals to remove layers of a material,which is a highly accurate manufacturing process used to produce high precision metal parts, it can produce any desired shape of high precision metal parts easily. Stainless steel etching, aluminum etching and cooper etching are the most popular metal etching.

Comared to other manufacturing processes, Chemical Etching/metal etching provides very close tolerances and high repeatability for features that are too small to achieve with conventional stamping processes, it is more cost efficient with shorter lead time, more design flexibility, and no need for deburring, because it eliminates the need for special tooling or process migration. It is an optimal choice for precision metal part manufacturing, regardless of prototyping or industrial production.

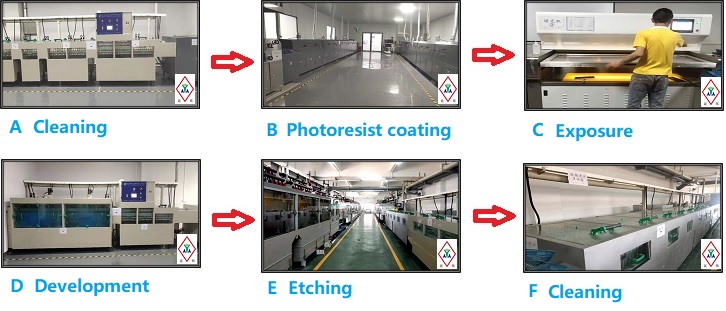

The chemical etching process:

1.A sheet of metal is chemically cleaned to ensure that it is free from potential contaminants

2.The sheet is coated with a film that is resistant to the chemical etchant called ‘photoresist’

3.The pattern to be etched is overlaid on the photoresist covered sheet, which is then exposed to UV light. The area that is not covered by the etched pattern is activated by the UV light and this will prevent the acid etching the material in this area

4.The sheet is put through a development stage where the unexposed photoresist is removed, leaving uncovered areas which will be etched by the acid

5.Developed material goes through the etching process where it is sprayed with the chemical etchant to etch the required pattern into the metal

Our Chemical Etching Capabilities

Continuous Reel-to-reel Etching

Coil Etching

Volume Etching

Production Etching

Precision Etching

Achievable Features and Specifications

Minimum Feature Size: 1.2x material thickness

Minimum Thickness: 0.0008″ (0.0203 mm)

Feature Tolerance: 10% of material thickness

Maximum Thickness: 0.0200″ (0.508 mm)

Maximum Part Width: 8″ (203 mm)

Maximum Part Length: 1,500′ (457 m)

Typical applications for Chemical Etching across industries:

Electronics & Semiconductor

SMT stencils

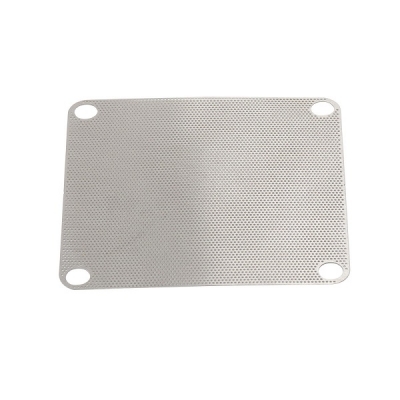

EMI/RFI Shielding cans

Shim, washer, spacer

Bus bars

Flexible circuits

Heat sinks

Apertures

Medical

Surgical blades

Lancets

(Micro) Needles

Automotive

Flat Springs

Flexture

For more information of our chemical etching process, and to find out how our expertise can support your project, just feel free to contact us or visit our another website www.etchparts.com

Custom your products freely and contact us

Visit our this website or www.etchparts.com to learn more about the various constructions and product features we can offer, and learn how we YanMing can customize your metal etching to meet and exceed your unique application requirements.

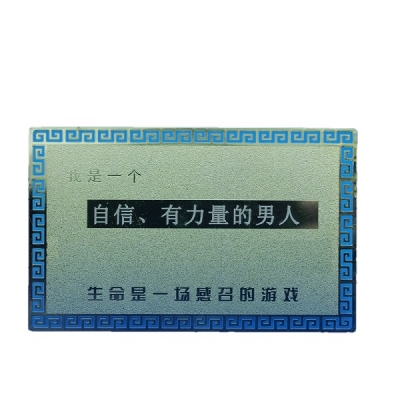

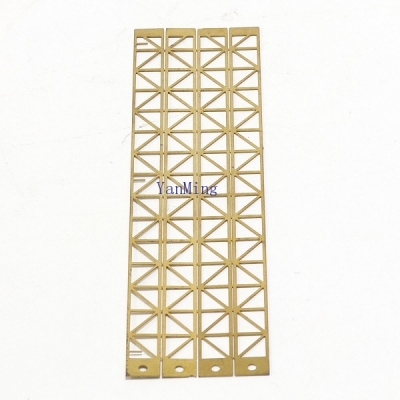

Metal Etching | Aluminum Etching | Stainless Steel Etching | Copper Etching | Etching Mesh | Micro mesh screens | EMI & RFI Shielding | Photo Etched Parts | Decorative Metal Crafts | Filter Screen | Encoder Disks | Engraved Metal Stencil | Lead Frame | Micro & Thin Shim |